Unparalleled 4K stereo imagery and ultra high resolution, with live and post-processed photogrammetry.

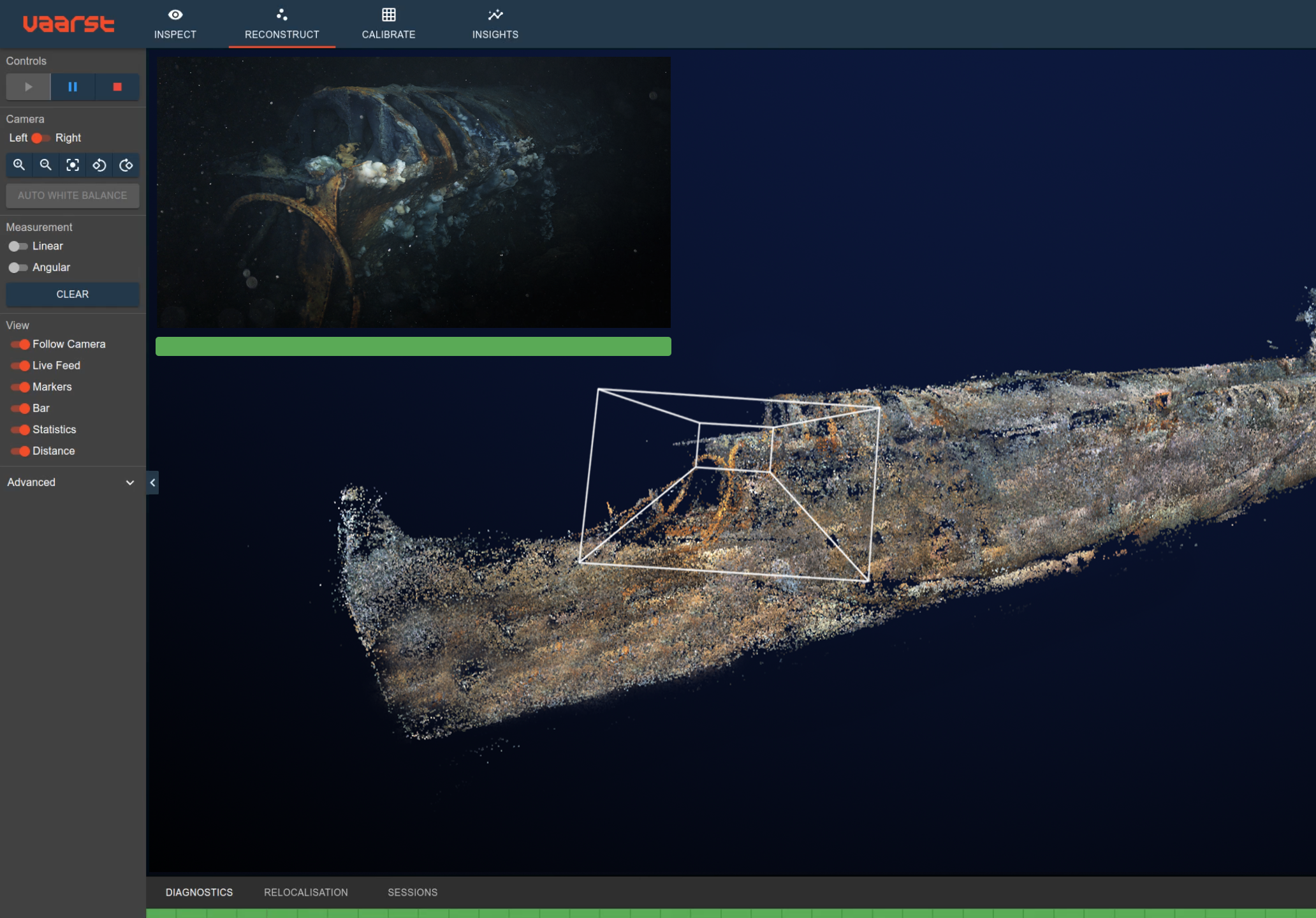

Persistent live reconstructions for complete 3D coverage

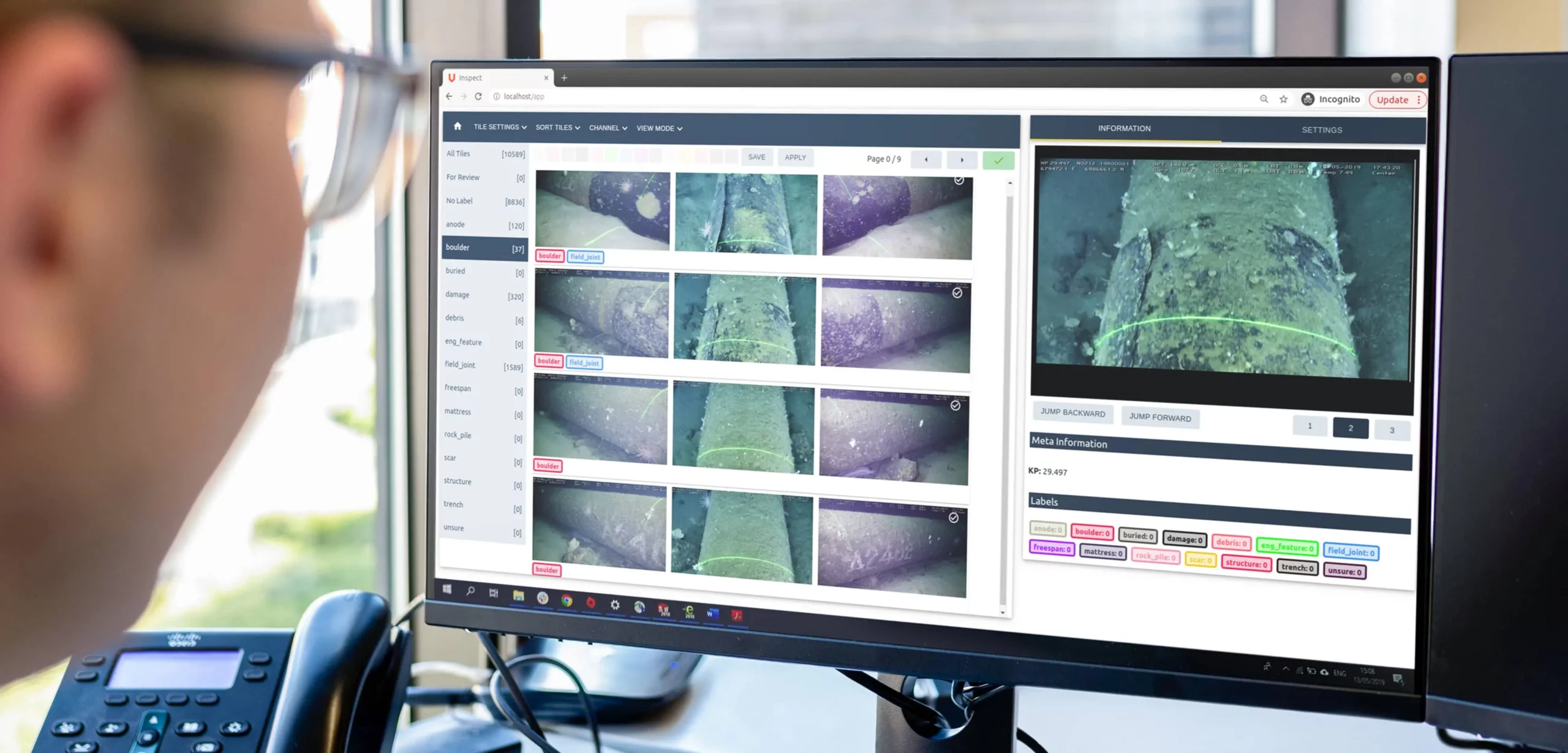

SubSLAM displays a persistent live 3D reconstruction that can be used as a real-time data coverage map. Interrogating the 3D model in real time allows you to verify data coverage and remediate data gaps while you are still on site, avoiding costly return trips and reshoots. Live streaming allows this valuable capability to be accessed by onshore personnel, empowering remote teams to conduct real time quality assurance.

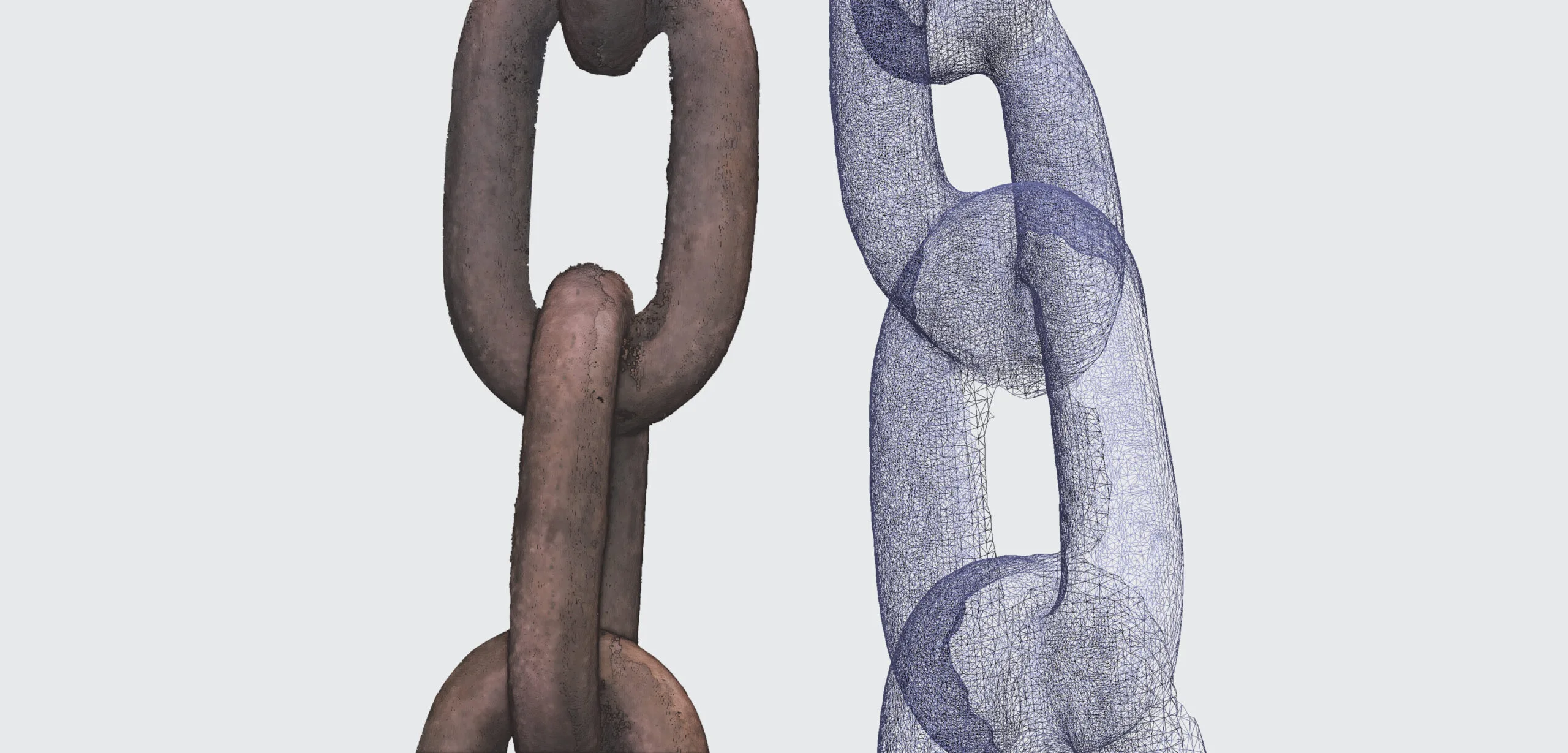

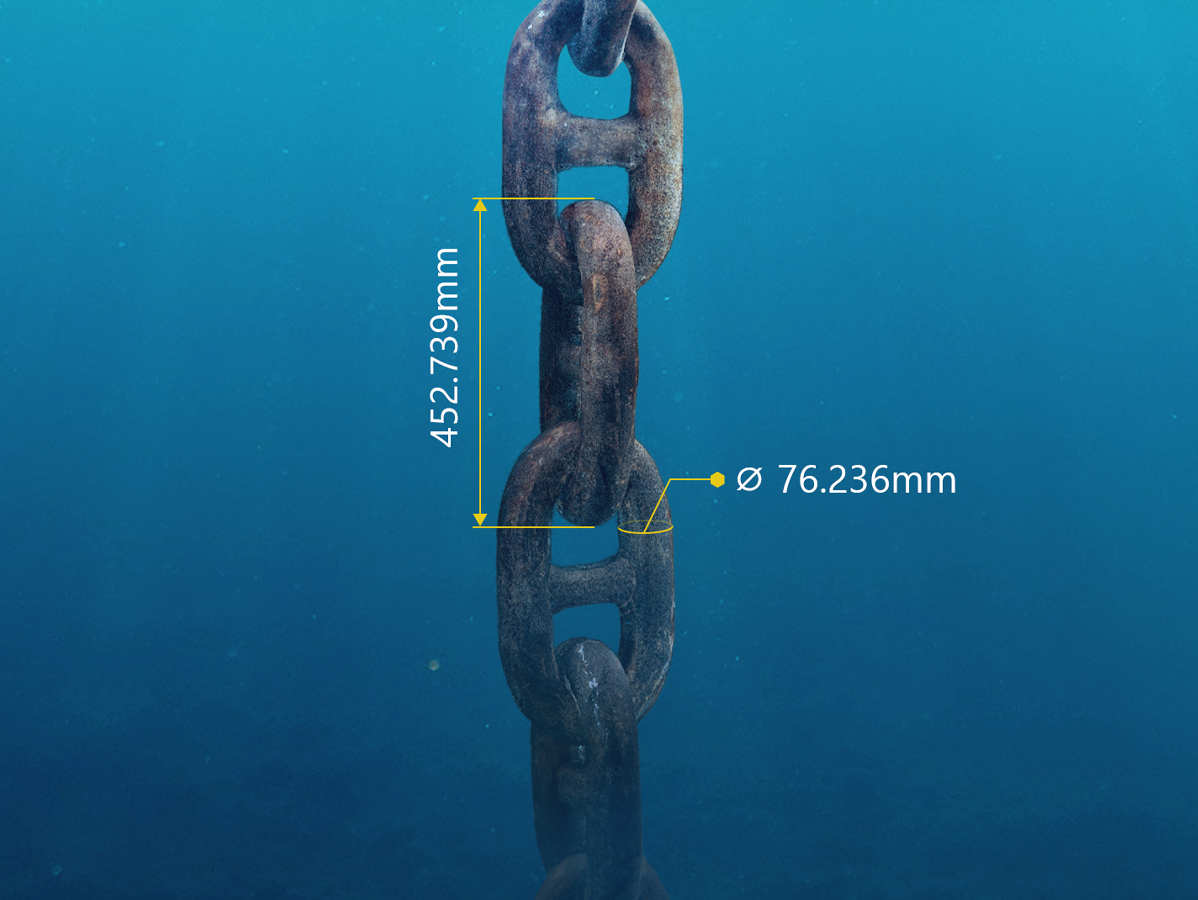

Precise contactless measurements

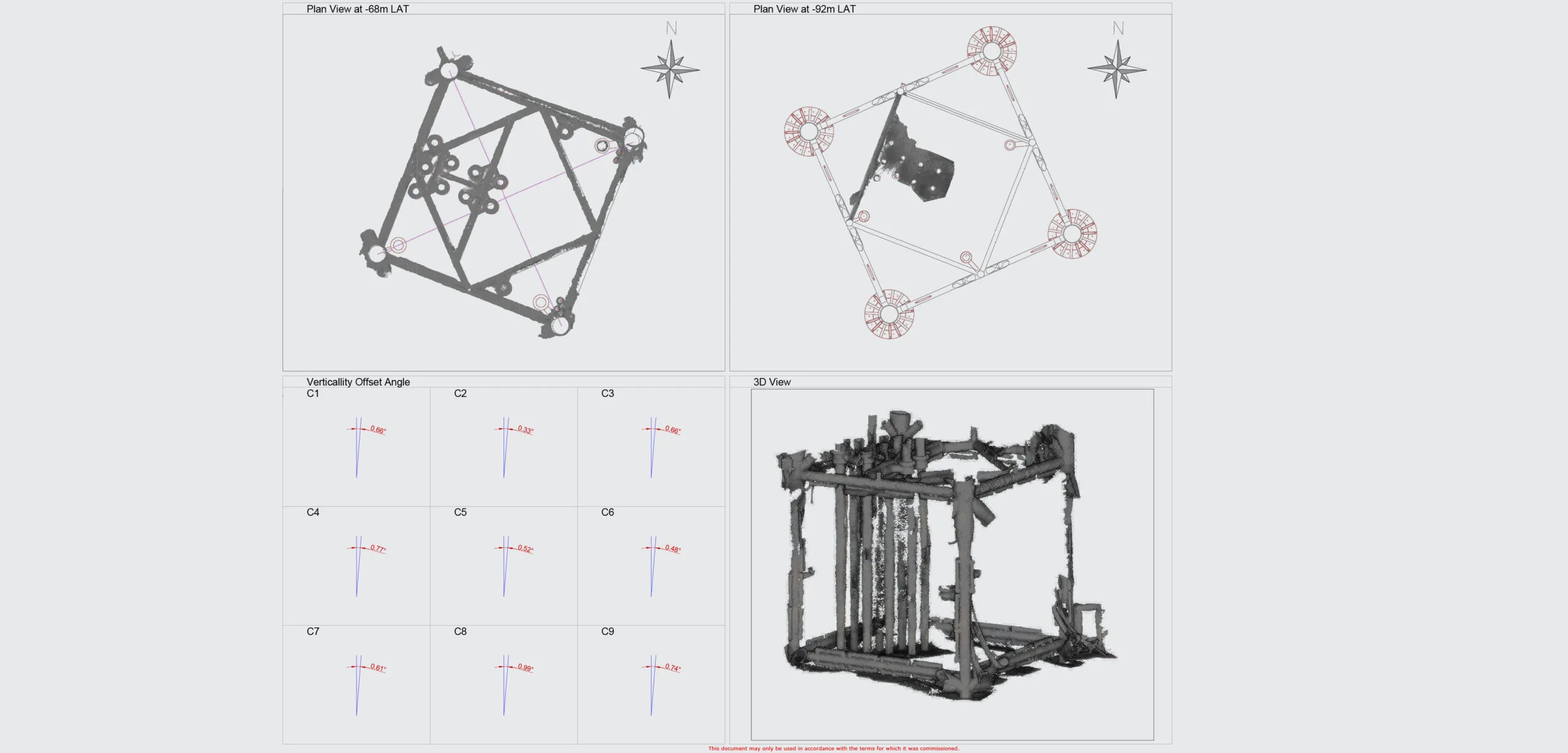

SubSLAM allows you to take contactless measurements with millimetre precision. Measurement accuracies of 0.1-0.15% have been verified and accredited by Bureau Veritas, for both defect measurements and distance metrology. High-precision 3D reconstructions can be used to reliably take repeated measurements between data collections. You can compare “as built” vs “as found” to confirm installation quality or tooling requirements. Conduct year-on-year difference modelling to understand structural degradation or marine growth accumulation.

Industry-standard data formats

Export video, stills, point clouds and meshed models in non-proprietary, industry-standard data formats. This provides you with flexibility to easily consume the data in your own toolsets and workflows. Datasets can be exported instantly, without the need for post-processing. Benefit from faster data availability, whilst also reducing data processing touch-time and associated costs.

Challenges overcome

Vaarst brings a wealth of knowledge and experience from offshore operations into the technical domain. We support all of our customers undertaking challenging projects in the best way possible.

Speak to a member of the team

Want to collect better subsea data, and do more with it? Speak to a member of the team to discuss your needs.