Rovco

Client: Rovco

Location: United Kingdom

Solution: SubSLAM® X2

Industry: Offshore Renewables

Rovco, a leading provider of ROV and hydrographic services, contracted by a major energy operator, undertook a baseline asset integrity survey at a newly constructed Offshore Wind Farm in the UK.

Rovco completed a baseline asset integrity survey of over 50 monopile turbine foundations and 1 offshore substation. The project encompassed 24-hour ROV operations provided over four weeks, deploying an ROV fitted with both 3D imaging sonar and Vaarst’s SubSLAM® X2 technology.

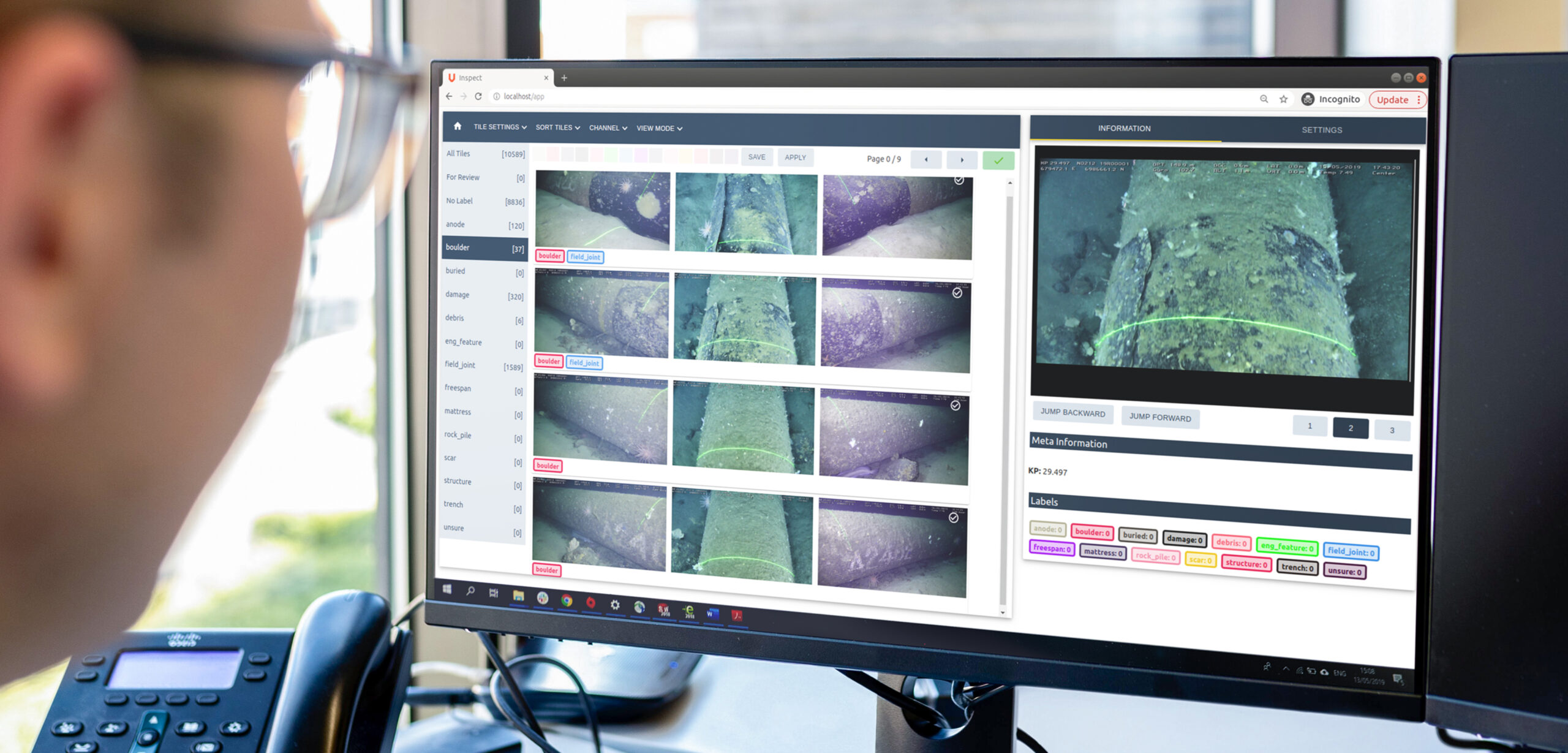

The data for this project was delivered via Vaarst’s data platform, allowing the end-client to view survey data libraries, reports, videos, and 3D point cloud reconstructions, as well as utilise intuitive tools to measure point-to-point distances, surface areas, and volumes, providing streamlined workflow for future asset management.

Challenge

The newly constructed Offshore Wind Farm aimed to develop a detailed baseline understanding of the condition and status of their subsea Balance of Plant (BOP) infrastructure across the entirety of the wind farm.

A comprehensive subsea investigation enables the timely detection of possible anomalies or defects that could deteriorate in the longer-term causing operational reliability issues. With early detection and access to highly accurate, illuminating survey data, 3D models and reports, informed asset rectification decisions can be made as required. This allows cost-efficient asset maintenance or repairs to be planned before any degradation and, where applicable, provides evidence for remedy claims to be made whilst the wind farm is under warranty.

Due to harsh environmental conditions at the site, such as poor subsea visibility and, at times, strong tidal currents, ROV surveys can be limited to slack water. Because of the low visibility and small operational window, the end-client was unable to collect the necessary data of their assets in a safe and cost-effective manner.

Solution

The Rovco team fitted their ROV with Vaarst’s SubSLAM® X2 System and operated the vehicle during the most significant slots of the operational tidal window, to maintain a safe working distance between the ROV and the structure. Thanks to Vaarst’s recent advancements in computer vision and AI, the technology utilises a unique 3D modelling technique that filters out suspended particles to focus on robust feature tracking for a more accurate reconstruction. This technique allowed the end-client and vehicle pilot to complete measurements in a fraction of the time, saving vessel days.

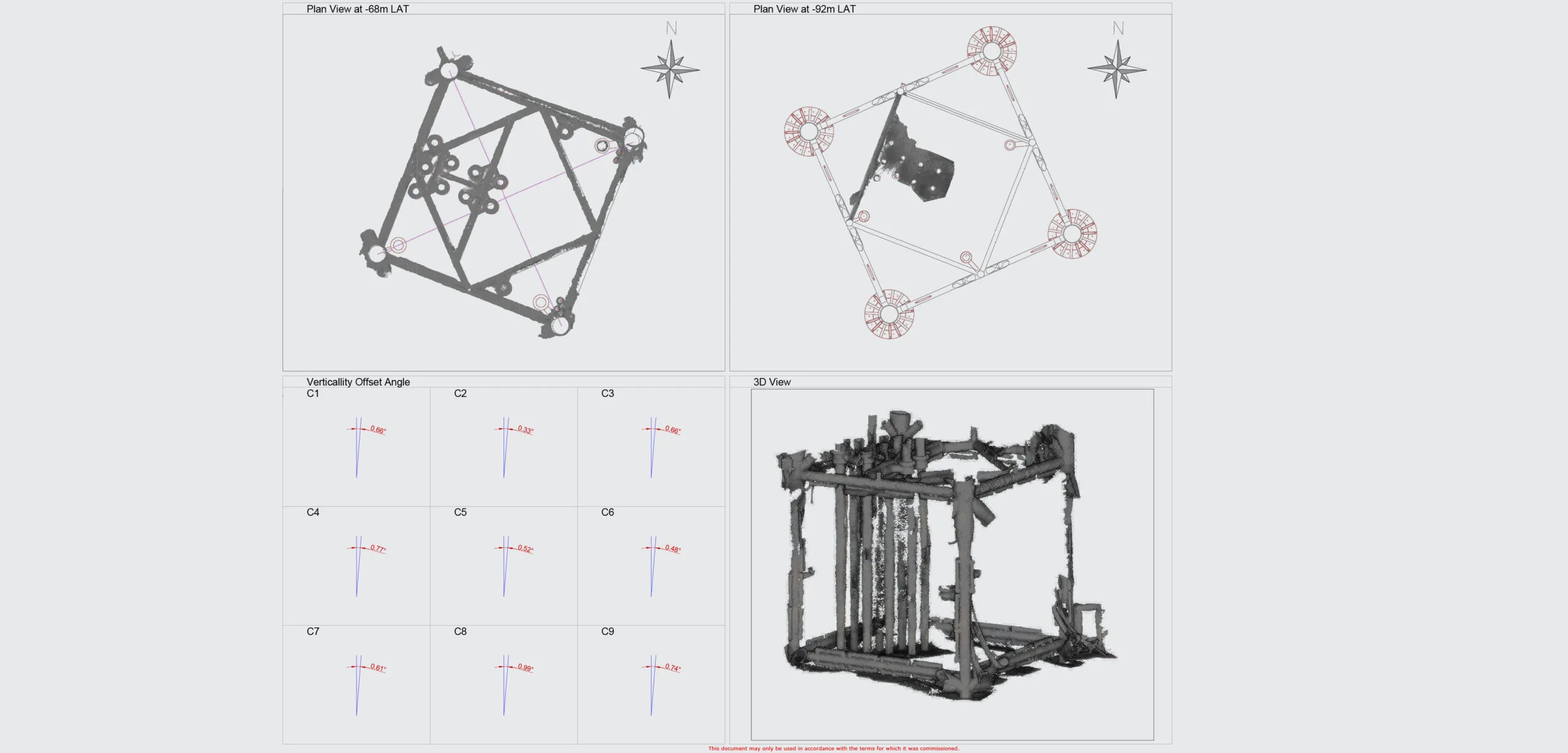

Post-processing the video data in Rovco’s Headquarters meant their team could create the highest quality photogrammetry models from the data collected by SubSLAM®. This focused on the key subsea components as specified by the end-client. The 3D models provided an ideal baseline to encounter changes moving forward, with overlay modelling in subsequent years.

Results

Rovco delivered the following data to the end-client via Vaarst’s proprietary data platform, providing a baseline regards overall asset integrity and enabling pre-empting of asset maintenance tasks:

- 60 detailed asset inspection reports

- 338 photogrammetry point clouds

- Over 50 sonar point clouds

- 2385 video files across the surveyed assets

Similar stories

We are proud to announce our collaboration with Red Sea Global (RSG), a visionary developer spearheading regenerative tourism projects worldwide.…