Live 3D point cloud data can be streamed to any device, anywhere in the world during inspections. Use the experience of onshore teams to ensure no return trips.

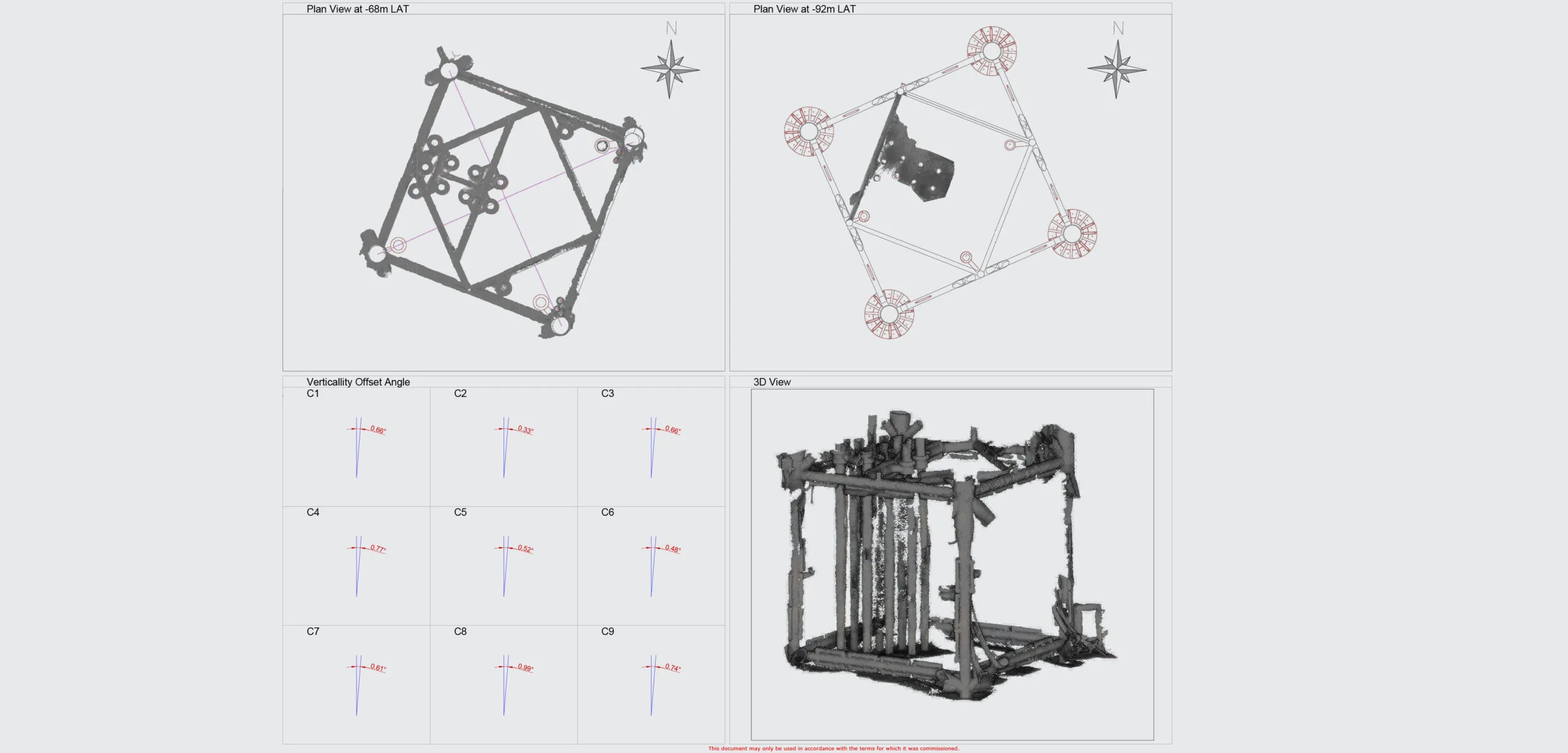

Planned and remedial inspections of jacket structures

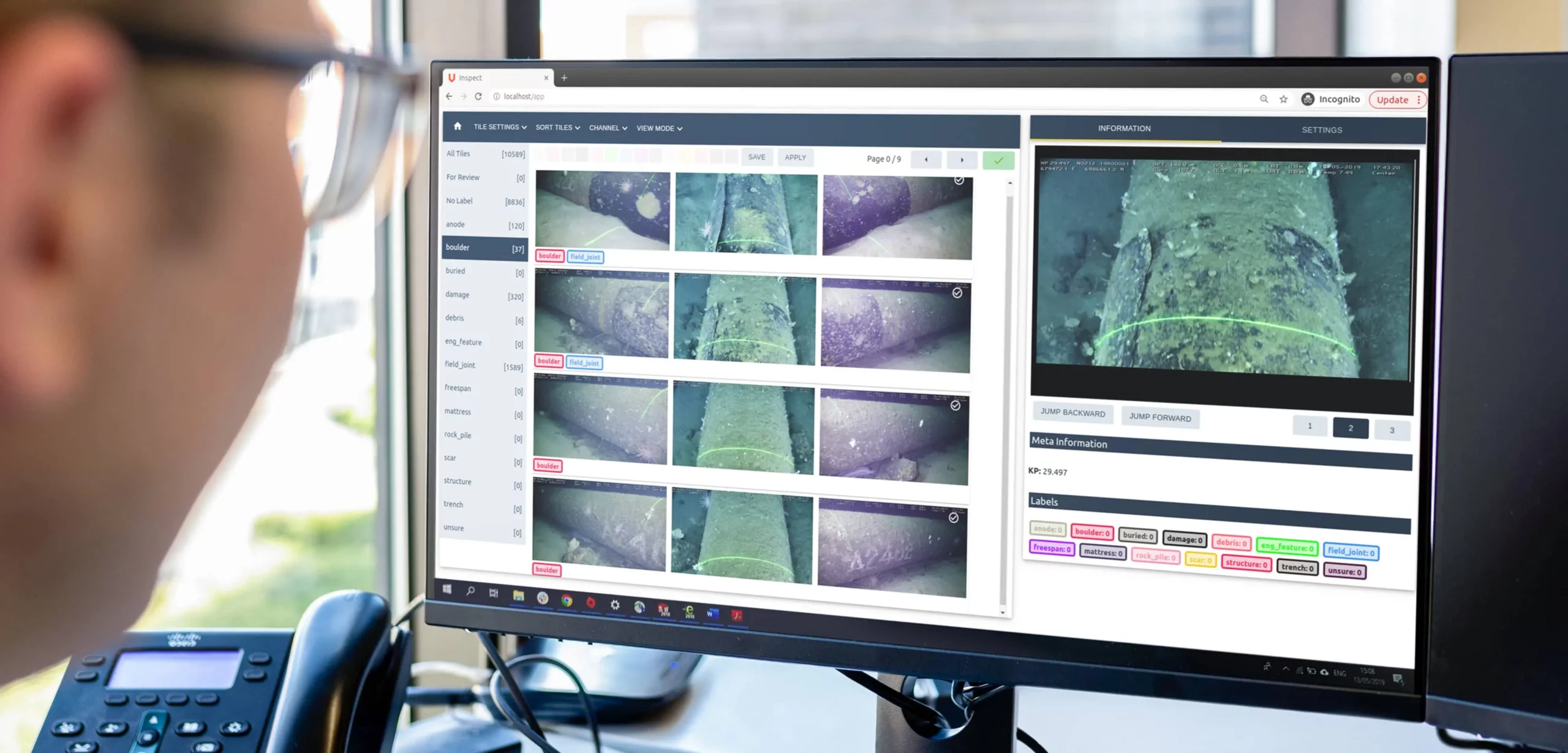

Straight forward data collection with no need to contact the structure. A high-definition 3D model is produced live while the ROV conducts a visual inspection which provides verification that all necessary areas have been completed. This reconstruction can be streamed on low bandwidth VSAT links for live viewing onshore by multiple stakeholders. If defects are detected plans for remedial engineering can be made from high precision, measurable post-processed datasets.

Repeatable data collection and processing procedures mean that models can be assessed year-on-year to quantitatively track changes over time. This insight can be vital in determining how quickly an issue may be propagating, informing teams of their remediation strategy.

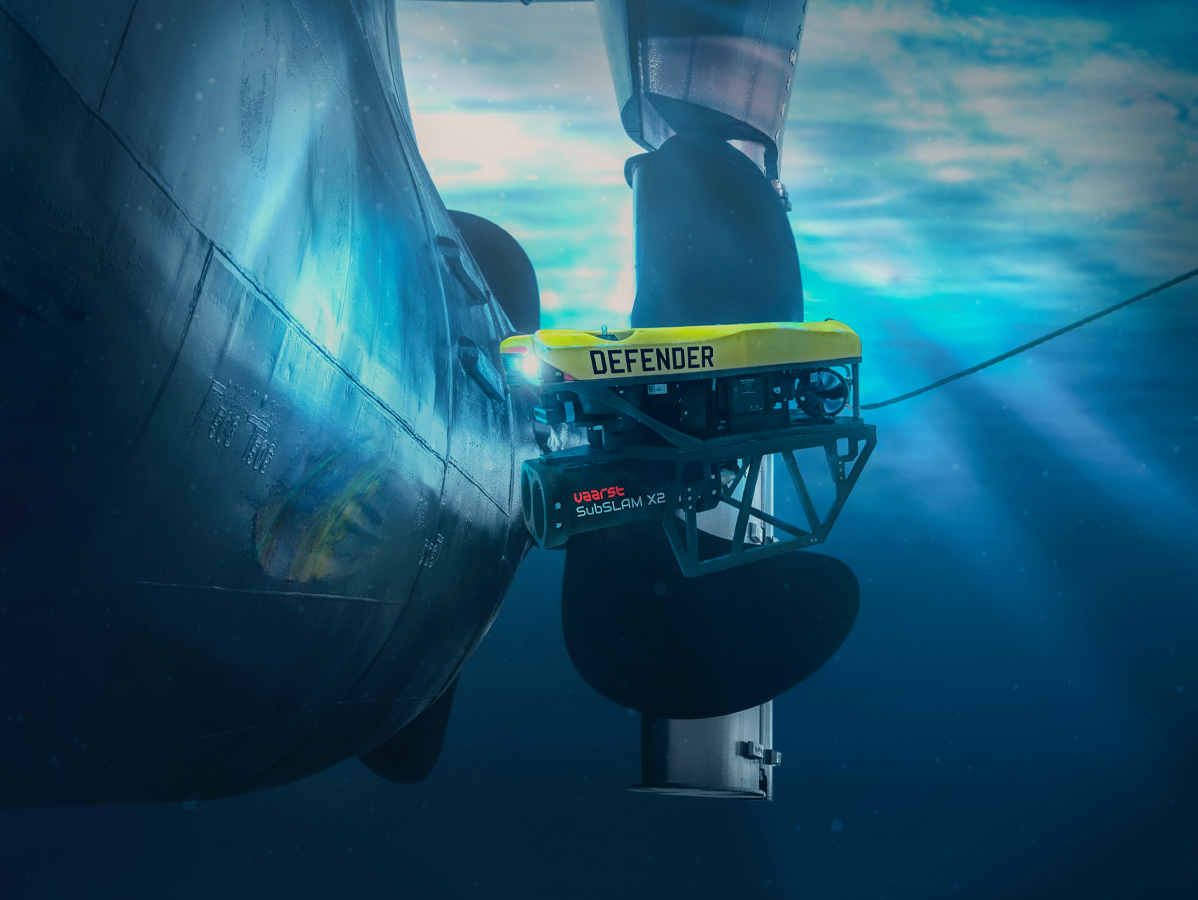

Inspection of ship hull for damage or marine growth

SubSLAM X2 enables a live and immediately measurable model. Alongside verified coverage, this allows operators to know that they have covered the whole hull and allows navigation back to features of interest. The ability to run ML models at the edge gives you semantic information in real time, telling you what you’re looking at and where it is located for instant decision-making.

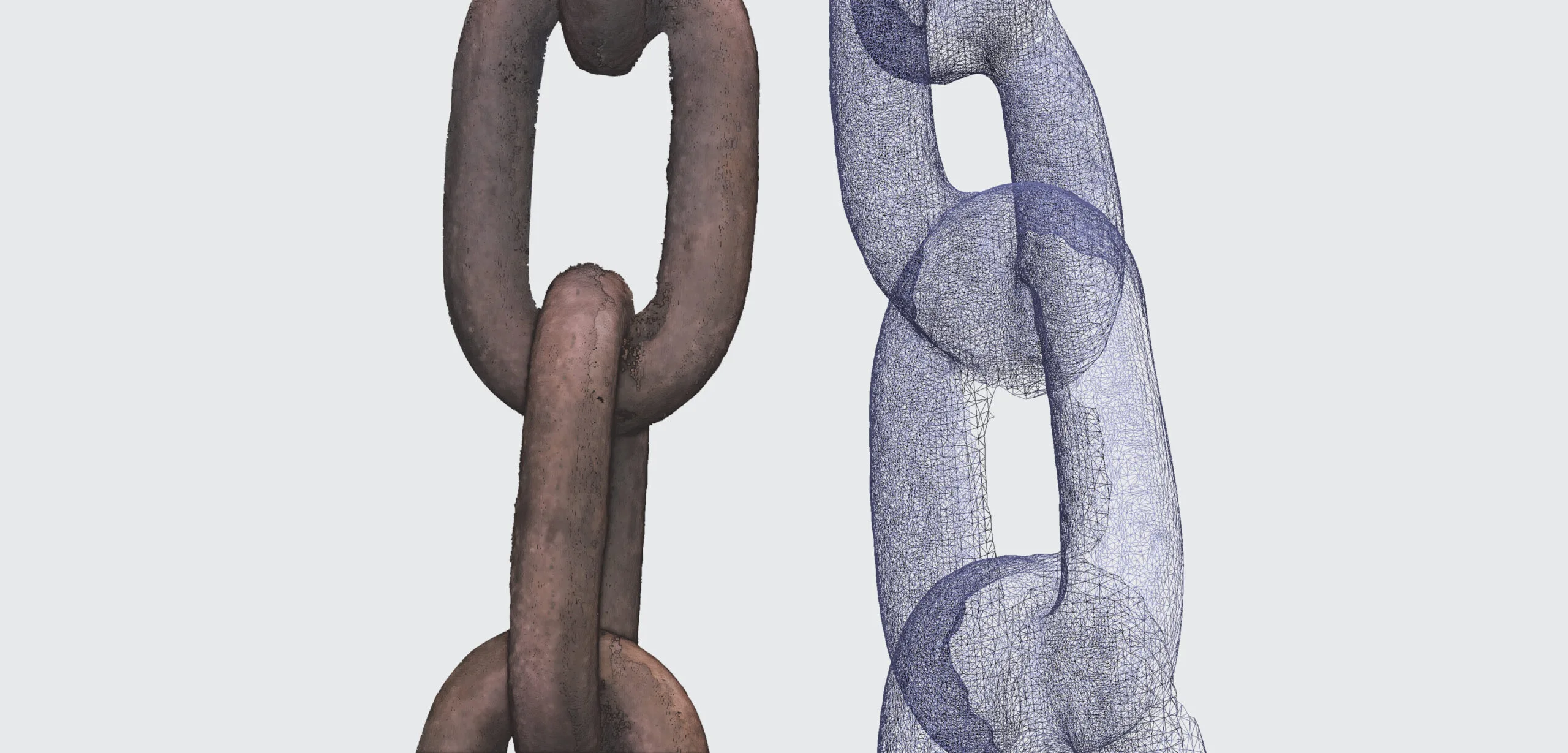

Salvage operations to determine condition and location of artefact of interest

Using SubSLAM X2 removes the need to undertake MBES and Side Scan Sonar surveys. High-resolution models are produced live in accurate geolocation, assisting clear decision making. These models are immediately measurable to sub-mm accuracy if required. Verified coverage of data collection ensures that all data is captured, avoiding costly return trips.

Challenges overcome

Vaarst brings a wealth of knowledge and experience from offshore operations into the technical domain. We support all of our customers undertaking challenging projects in the best way possible.

Speak to a member of the team

Want to collect better subsea data, and do more with it? Speak to a member of the team to discuss your needs.