SubSLAM® for visual inspection of mooring chains

Client: Anonymous

Location: United Kingdom

Solution: SubSLAM® X2

Industry: Oil & Gas

A major Oil & Gas operator required a visual inspection of multiple mooring chains to be undertaken, to evaluate the wear of contact points. To do so, a contracted ROV service provider powered by Vaarst technology, SubSLAM® X2, was chosen to undertake the survey and collect the highest quality data possible.

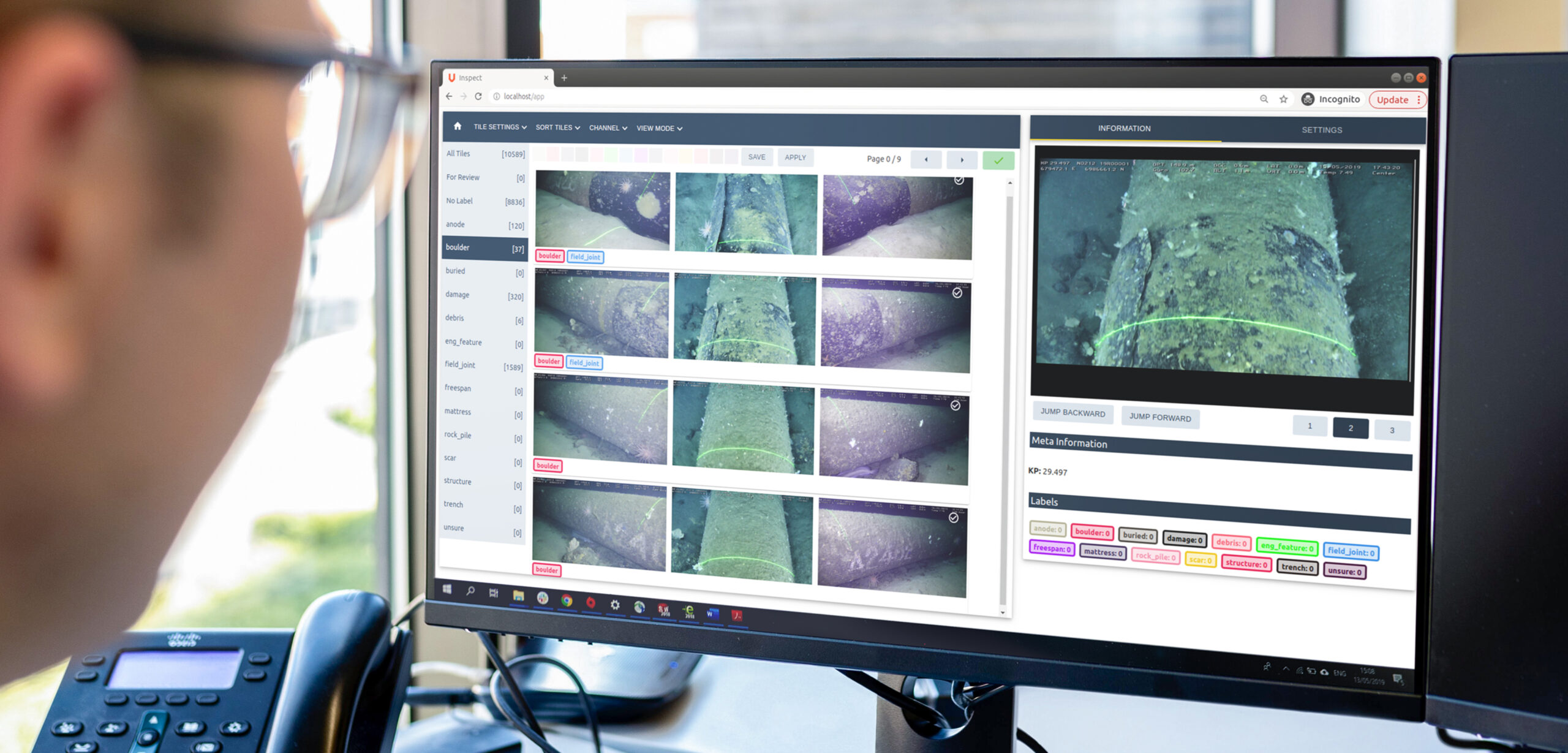

The data for this project was delivered to the client via Vaarst’s data platform, allowing the end-client to view survey data libraries, reports, videos, and 3D point cloud reconstructions, as well as utilise intuitive tools to measure point-to-point distances, surface areas, and volumes, providing a streamlined workflow for future asset management.

Benefits

- Millimeter accurate 3D models of mooring chains

- General Visual Inspection reports and data of complete structure and components for asset integrity stored in a secure cloud-based data platform

Challenge

A comprehensive subsea investigation enables the timely detection of anomalies or possible defects that could in the longer term deteriorate causing operational reliability issues. With early detection and access to highly accurate, 3D models and reports, informed asset rectification decisions can be made as required. This allows cost-efficient asset maintenance or repairs to be planned before any deterioration becomes critical.

The location of the mooring chains to be inspected was located in a hazardous area, in close proximity to the asset in question. This made the survey complicated to undertake, having to operate in small tidal windows, to maintain a safe working distance between the vehicle and the structure.

Solution

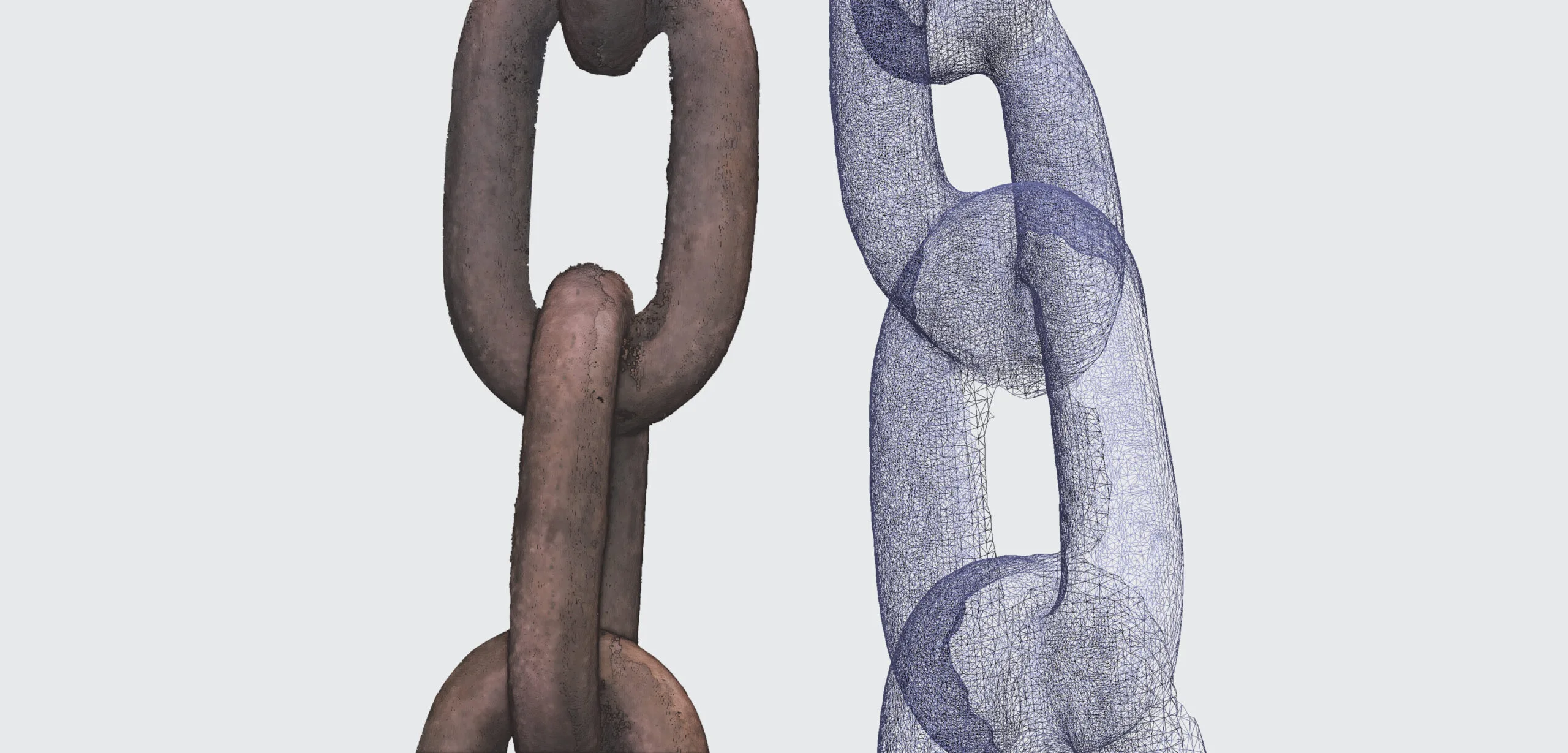

The contractor, in order to provide the level of detailed required by the end-client, utilised Vaarst’s technology, SubSLAM® X2. The system was able to deliver live underwater point cloud data, perfect positioning of the vehicle at all times and millimeter accuracy of the assets in question.

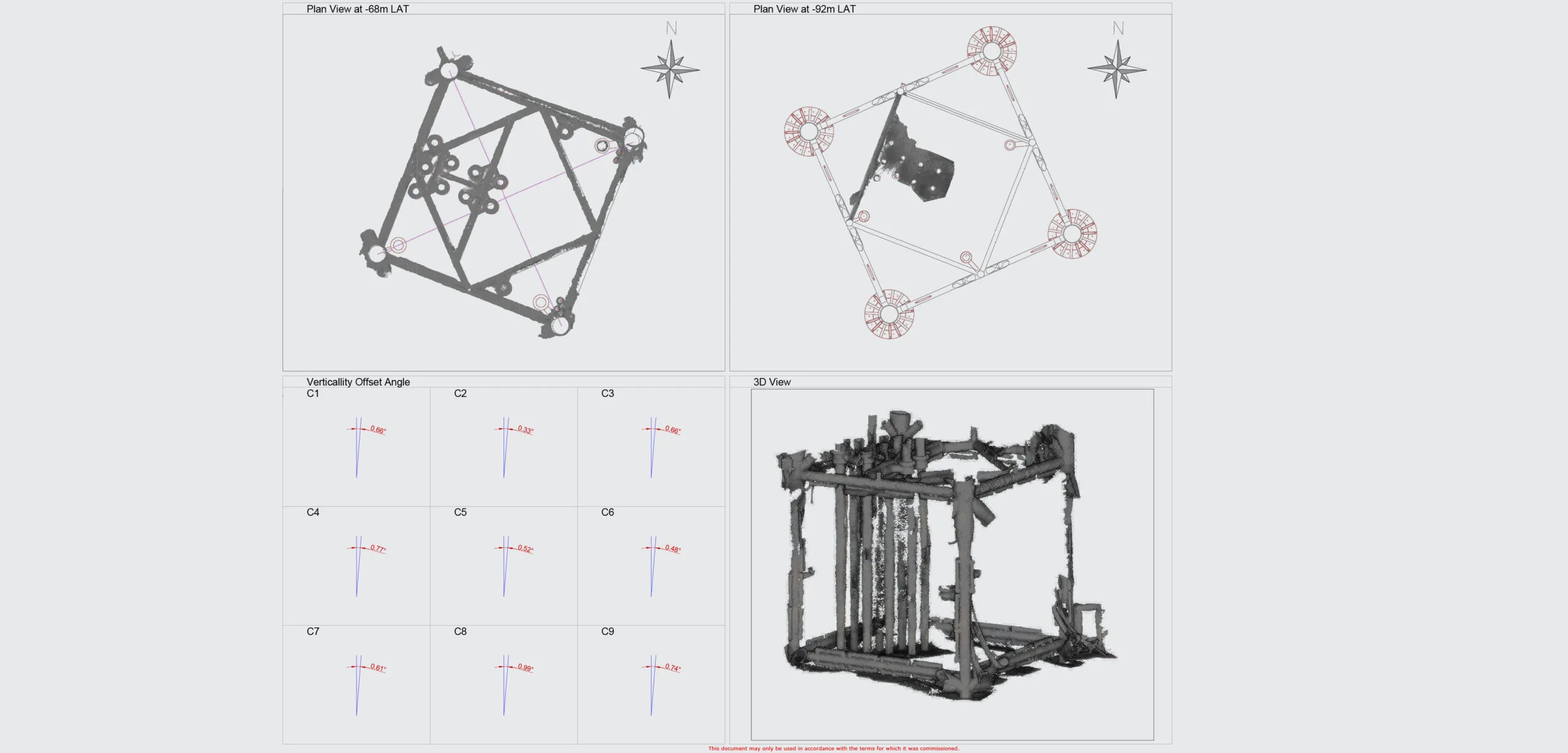

SubSLAM® X2 enabled quantifiable measurements to be undertaken and compared to previous year inspections, enabling change detection. The data collected will also be compared with future year inspections. Live 3D reconstructions were collected offshore to ensure adequate coverage of the chain for high accuracy post-processing and detailed analysis.

To help identify areas of wear, perfect chain links models were used, which were measured for length, width and depth depression. This was compared to the previous year measurements to capture changes to be accurately monitored.

Results

Thanks to Vaarst’s technology, the 3D models provided, were an ideal baseline to encounter changes moving forward, with overlay modelling in subsequent years, providing a baseline regards overall asset integrity and enabling pre-empting of asset maintenance tasks. Via our data platform, the contractor provided the following data to the end-client:

- Upper chain links were modelled as continuous sets

- An additional 50 link intervals were measured

- The chain links were sliced into vertical and horizontal sections to allow measurement of the inter-grip and chain bar to be undertaken accurately

- To ensure accuracy, best fit geometry was used to enable comparison against a model

Similar stories

We are proud to announce our collaboration with Red Sea Global (RSG), a visionary developer spearheading regenerative tourism projects worldwide.…