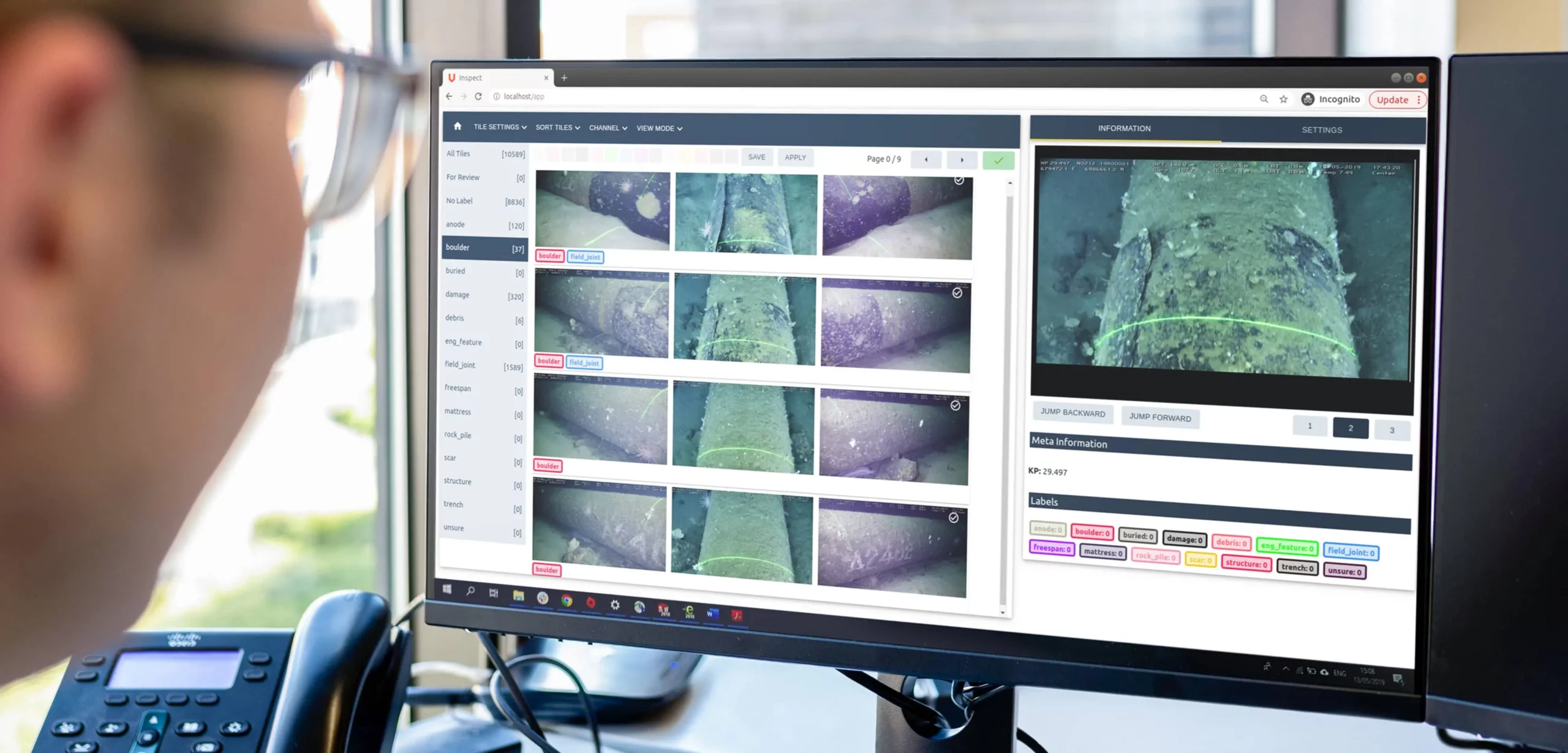

The easy-to-navigate platform provides an intuitive and contextual view of your data.

Rapid analysis of subsea infrastructure

Subsea cables, pipelines and structures are a critical component for subsea infrastructure. Interpreting video footage to ensure there are no breakages, missing parts or damage is laborious and prone to human error. Reporting on identified issues is unwieldy and requires video frames to be extracted and geolocated from long video files.

Vaarst platform users can save hours of manual video analysis using our self-serve classification tools which are capable of assessing over 100km of pipeline footage in a matter of hours. Powered by machine learning, our tools are trained on hours of subsea data in all manner of conditions. Our AI models can outperform humans at identifying breakages, field joints, and anomalies.

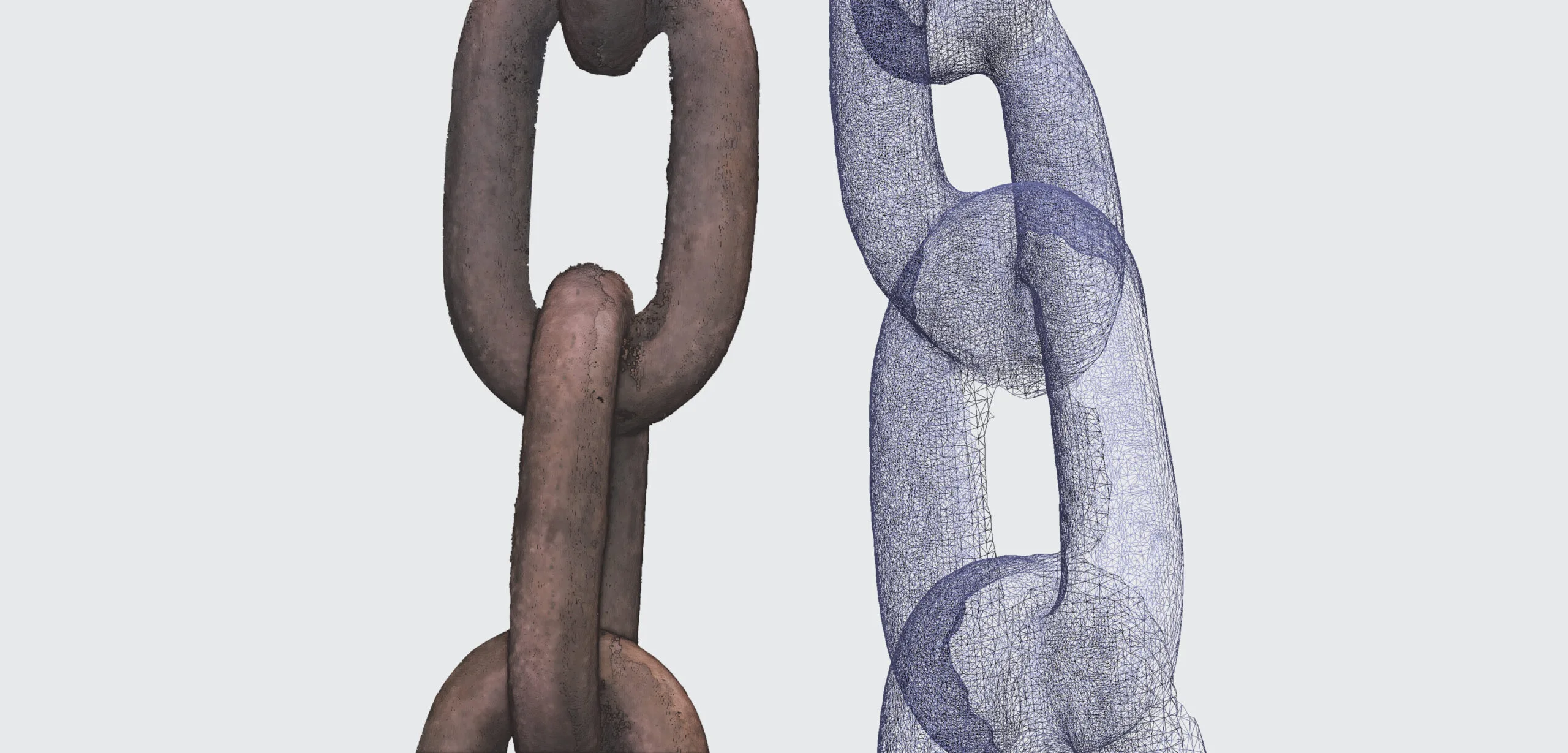

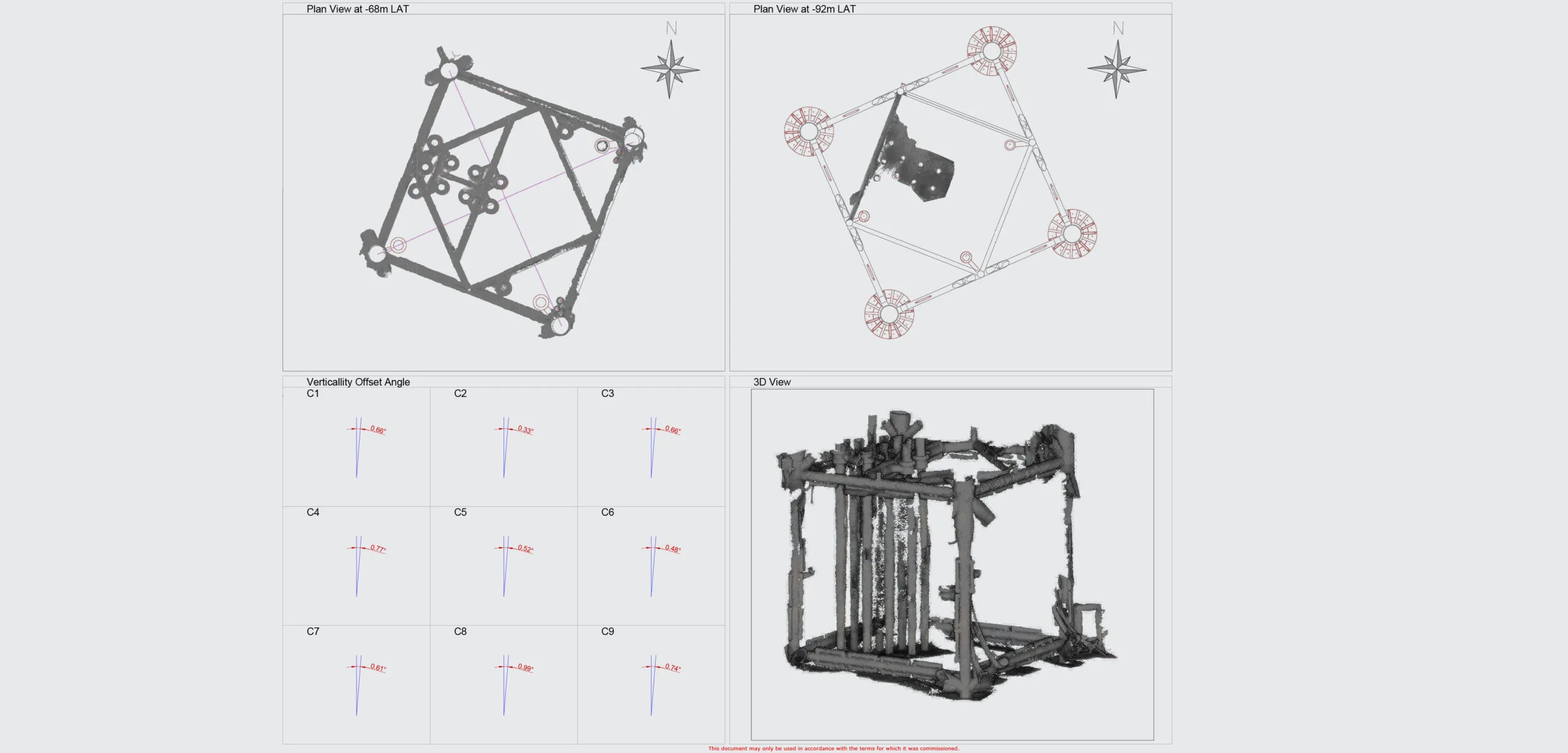

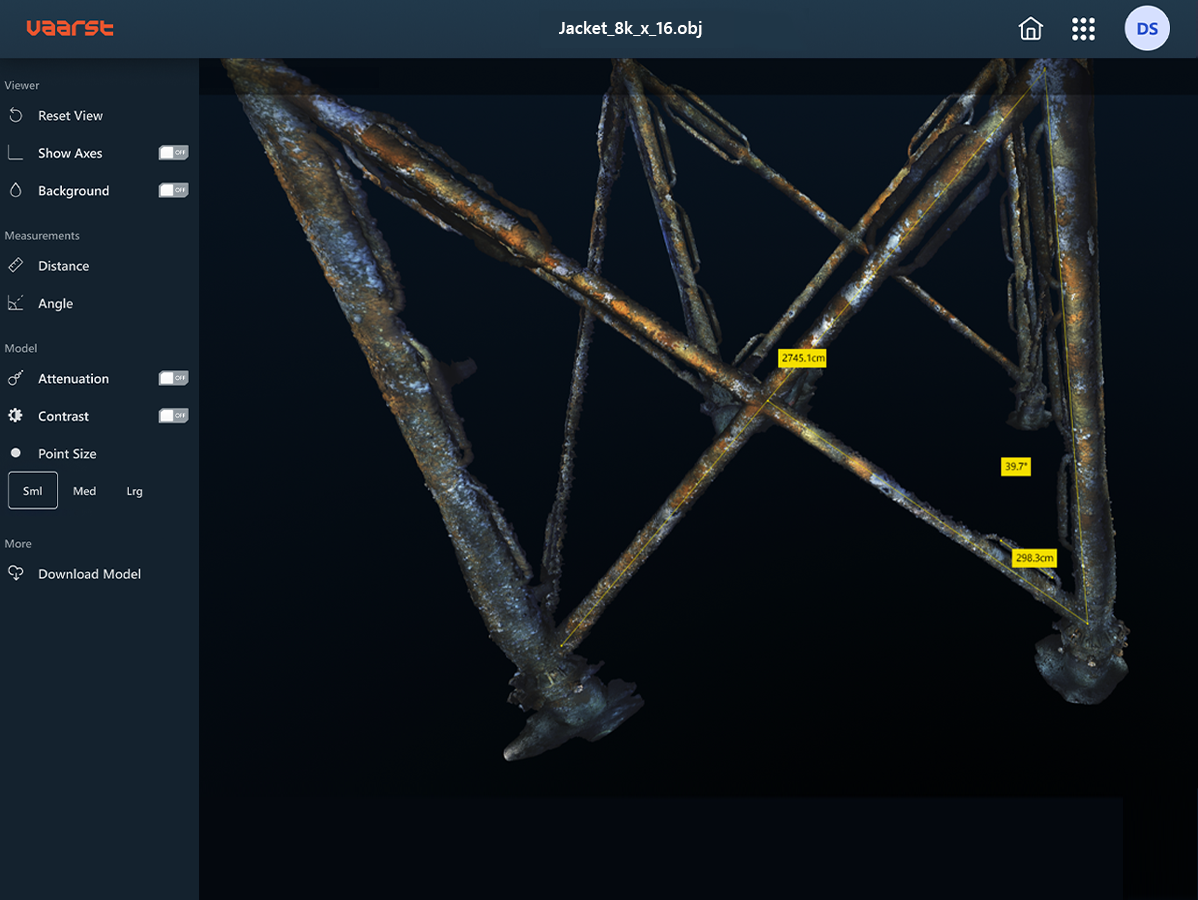

Replace PDF reports with enriched 3D models

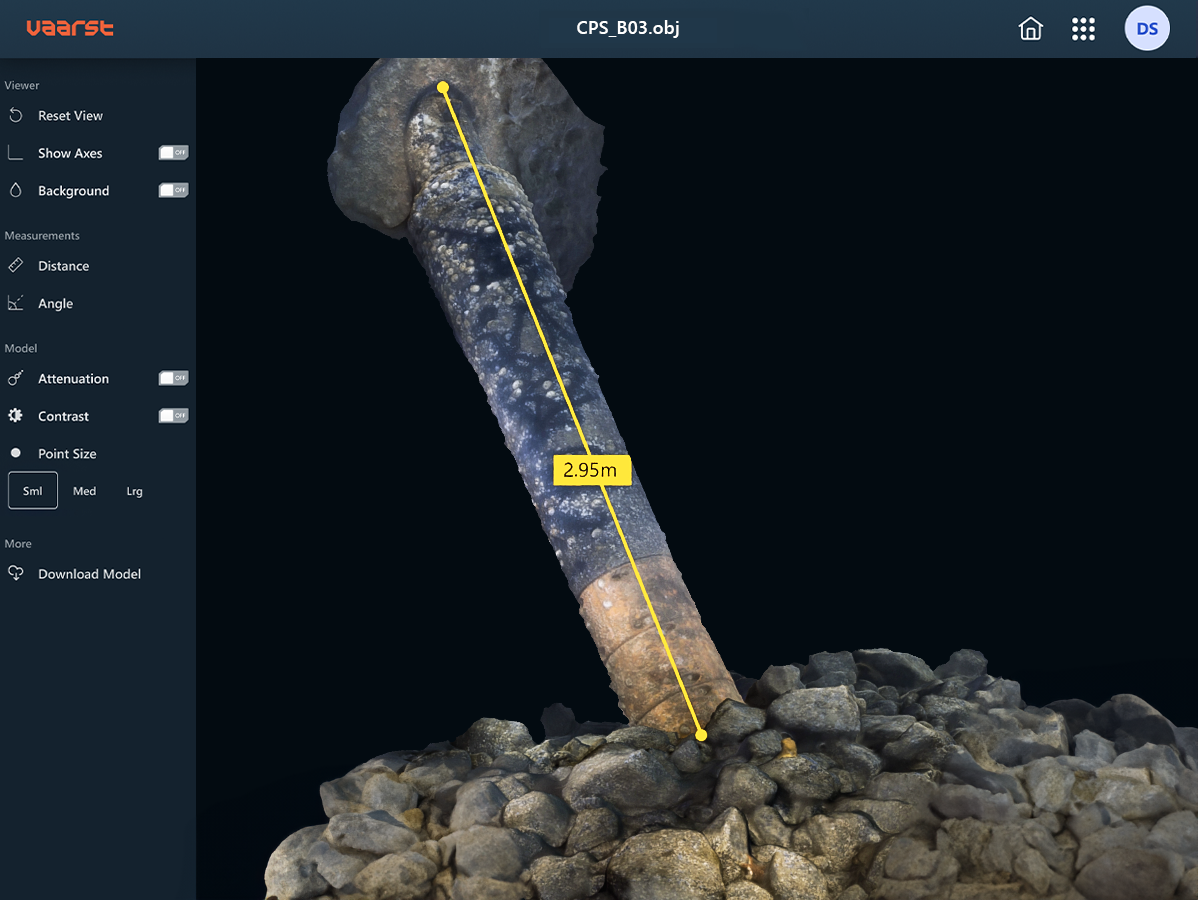

Help align with non-technical stakeholders and improve engagement using 3D models that can be navigated in all dimensions, measured for distances, angles and volumes as well as be compared quantitatively with existing datasets. Presenting data in 3D makes it much easier to communicate the status of an asset with non-expert audiences, and by using our Data Platform, you don’t need specially trained personnel or expensive third parties.

The Vaarst Data Platform streamlines the process of fault detection, project planning and asset remediation.

Predictive insights for UWILD

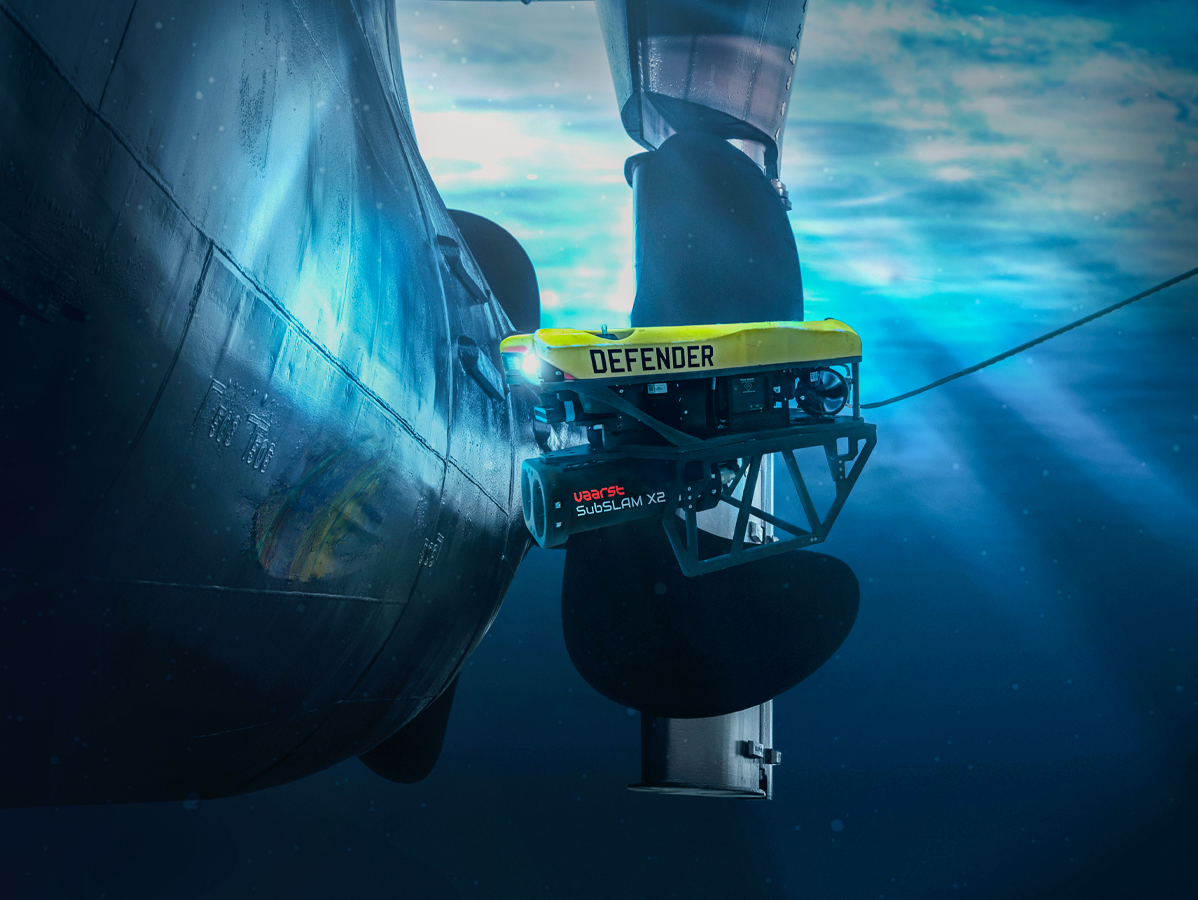

Commercial vessels must be inspected for abnormalities below the waterline once every two to five years. Data from previous inspections isn’t always available, creating a lack of continuity between inspections. The Vaarst Data Platform addresses this problem.

3D representations of vessel hulls, marked up with metadata including anomalies, can be uploaded for easy retrieval in the Vaarst Data Platform. This database enables operators to monitor abnormalities throughout the vessel’s lifetime, helping vessel owners and authorities keep track of vessel condition.

Challenges overcome

Vaarst brings a wealth of knowledge and experience from offshore operations into the technical domain. We support all of our customers undertaking challenging projects in the best way possible.

Speak to a member of the team

Want to collect better subsea data, and do more with it? Speak to a member of the team to discuss your needs.